Complete Guide to Choosing the Right Laser Nozzle

How nozzle size, shape, and material impact cut quality, speed, and pierce reliability.

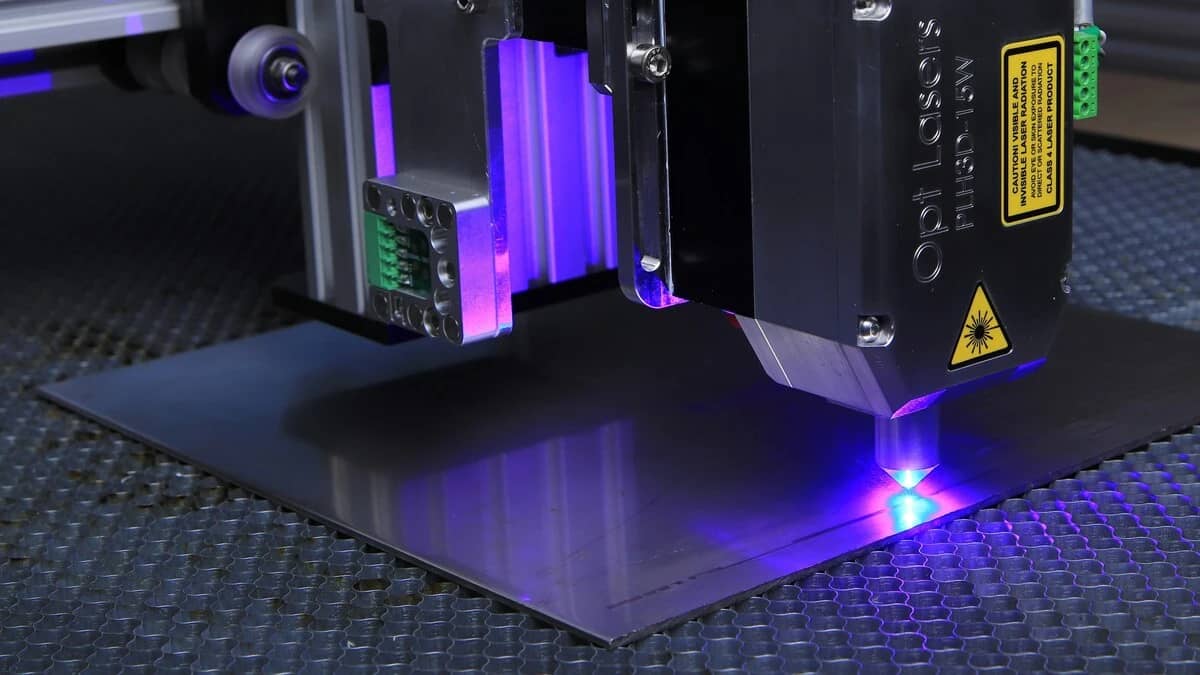

Why the Nozzle Choice Matters

The nozzle governs gas flow, edge quality, and pierce stability. A poor match causes dross, burrs, and extra cleanup.

Match nozzle diameter to kerf and assist-gas pressure. Smaller orifices improve edge finish; larger ones support higher speeds and thick plates.

How to Select the Right Nozzle

For mild steel with oxygen, favor smaller diameters for cleaner edges; for stainless/aluminum with nitrogen, larger orifices help evacuation at high speed.

Double-nozzle designs improve cooling and coaxial flow in high-power jobs; single-nozzle is often enough for thin sheets and prototypes.

Practical Setup Tips

Keep the nozzle face clean and flat; even micro-dents disturb gas symmetry.

Recalibrate stand-off after any nozzle change and verify focus height with a feeler gauge or auto-height check.

Maintaining Nozzle Performance

Inspect the nozzle orifice under magnification weekly to detect wear or damage early.

Avoid over-tightening, which can warp the nozzle seating surface and misalign the gas jet.

Solving Common Nozzle Issues

If you see excessive dross, check for nozzle damage, debris inside the orifice, or incorrect stand-off height.

For inconsistent pierces, ensure the nozzle is centered over the beam path and replace any warped or burned tips.